Faulty Williams ASIC? Don't toss it yet!

During the WPC era, Williams used an Application Specific Integrated Circuit or ASIC.

ASICs are typically custom designed circuits that are used to replace entire sets of ICs.

Typically they are very expensive to design and build. In order for these to be

economically feasible, they must be purchased in huge quantities.

As long as you have a product that uses large quantities of these IC's (i.e. Williams

when they were making tons of these CPU boards) then you can save money by replacing

several smaller IC's with one larger IC.

If you only have a few made then the costs can be astronomical! The current going

rate for a single Williams ASIC is in the $40 to $50 range. Yet, that's a bargain

compared to what it would cost to have only one custom built from the factory.

When many people suspect a bad ASIC, the first thing they do is go out and buy a

replacement. Unfortunately, many of these people may be needlessly throwing money

out the window by purchasing and replacing an expensive component when there may

be nothing wrong with the original.

The Williams ASIC is built within a Plastic Leaded Chip Carrier or PLCC type package.

This ASIC is installed on the Williams CPU board using a PLCC IC socket.

Theoretically, using this PLCC socket made the board easier to repair. But, there's

a definite downside to using PLCC sockets.

When PLCC type IC's are shipped from the factory, they are typically shipped in an

IC 'tube' along with approximately 20 others in the same tube.

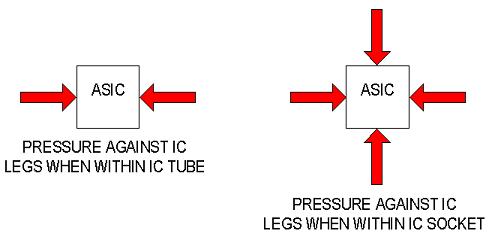

As these parts are shipped in tubes and as they are installed in IC sockets,

there is a constant side pressure on the PLCC IC legs. The following image shows

the pressure against these IC legs:

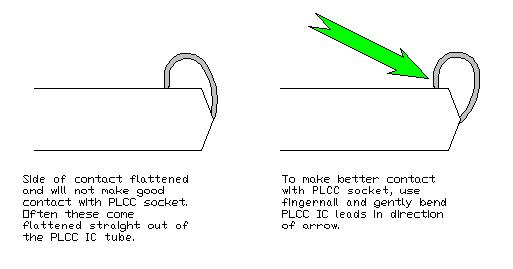

Over time, this constant pressure flattens out the legs of the PLCC IC's

enough to where they eventually begin to lose reliable contact between the IC

leg and IC socket.

Many people misdiagnose this as a bad ASIC or bad IC socket.

Often the problem can easily be corrected by spreading the IC

legs back to a point where they make reliable contact with the IC socket.

Refer to the following image for how to re-bend the PLCC legs:

As you can see in the first image, the rounded PLCC IC legs are nearly flush with the side of the IC. This means there is very little pressure between the PLCC IC legs and the IC socket. A lack of pressure will cause poor contact between the PLCC and the IC socket resulting in intermittent operation or complete failure. In the second picture, the PLCC IC legs have been extended out horizontally. This provides a large increase in pressure between the IC legs and the IC socket. Often - this fixes the problems with the Williams ASIC.

Login Status

Login Status